Drive Units

As the part of a loudspeaker that actually produces the sound you hear, using the correct drive units is absolutely vital to developing truly high resolution product. Read on to find out how PMC develops these highly precise and advanced components to work optimally within our ATL designs.

Bass drivers & ATL

Transmission line speaker cabinets behave in a very different way to most ported and sealed designs, and interact with their corresponding drive units in a highly complex manner. As a result of this, the design goals and resulting parameters required for a bass drive unit intended for a transmission line speaker are very different from those specified for most other designs. To achieve these specific requirements and gain the best performance from our transmission line cabinets, PMC designs and optimises every singly bass driver we use in tandem with its intended cabinet, ensuring that the two work optimally together, giving the best possible bass performance from the speaker.

Drive unit Parameters

We measure an array of drive unit parameters rapidly, and non-destructively utilising a software-controlled laser displacement sensor. This allows us to optimise a drive unit through iterative design to better integrate with the intended ATL cabinet. The laser displacement sensor also allows us to measure the drive unit to ATL coupling efficiency (the interaction between the drive unit and ATL) and produce metrics of how efficiently they are working together. By measuring how much acoustic output is obtained from the ATL vent for a given excursion input from a drive unit, we can evaluate how efficiently the drive unit is coupled to the air inside the ATL and adjust parameters of the design to maximise this efficiency, giving our loudspeakers the best possible combination of bass extension, headroom and low distortion.

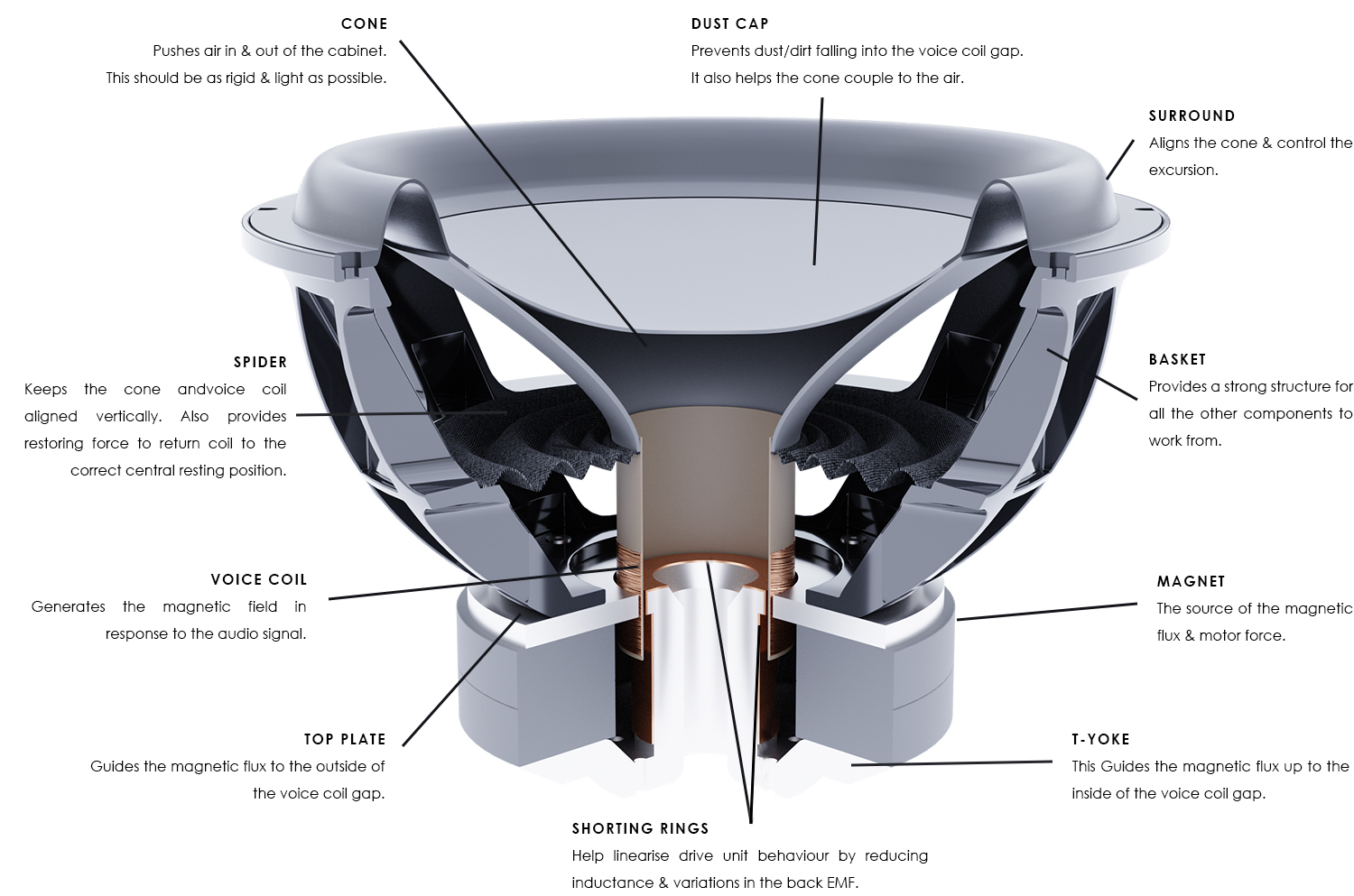

Inside a drive unit

Mid/High

Frequency drivers

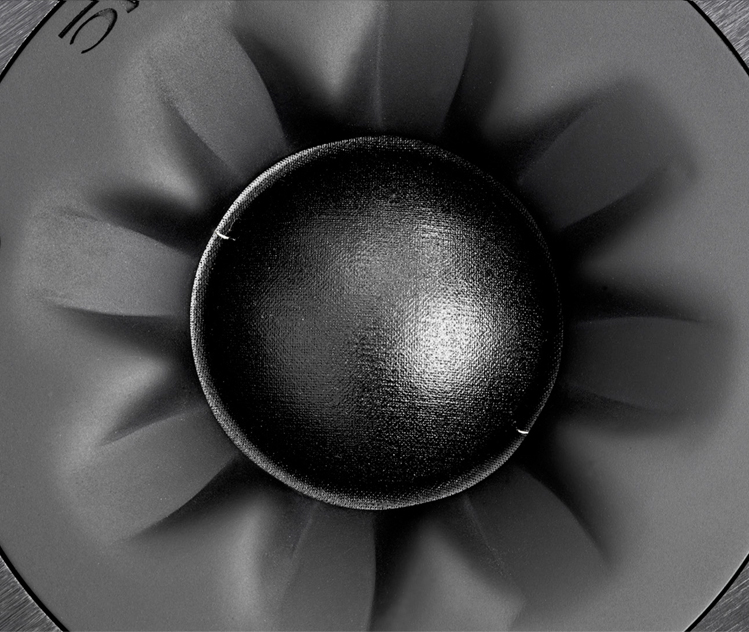

All of the mid and high frequency drive units in PMC products are soft dome designs, giving a consistency of behaviour and sound quality across all of our products. Soft dome tweeters have become the most popular design across the industry for very good reasons – they have low moving mass, allowing for high sensitivity and excellent time domain performance with no overhang or ringing. They have excellent damping on the diaphragm, meaning that there are no sharp breakup modes as are often seen on either rigid domes or cones, giving a very natural and smooth audio presentation with no fatiguing shrillness or edginess to the sound.

Most manufacturers only use dome diaphragms for their high frequency drive units, as there is a significant cost and complexity involved with designing and manufacturing larger dome midrange drivers. However, at PMC we realised that the potential benefits that a large, soft dome midrange drive unit can bring are worth the increased complexity and challenges for development, so we use our own designed soft dome midrange drive units in all of our 3-way products, even going as far as to manufacture our famous PMC75 drive unit entirely in-house.

Why use a dome over a cone?

There are many benefits to using a soft dome midrange driver over an equivalent rigid cone design:

The large diameter voice coil attached at the edge of the dome gives superior control and power handling compared to a small voice coil attached at the centre of a cone. The moving mass of the diaphragm will be much lower than that of an equivalent cone midrange, allowing for much higher sensitivity and more controlled motion. Also, the radiation characteristics of a dome midrange are different to those of a cone drive unit, giving a smoother, wider dispersion at mid and high frequencies than a cone driver can achieve.

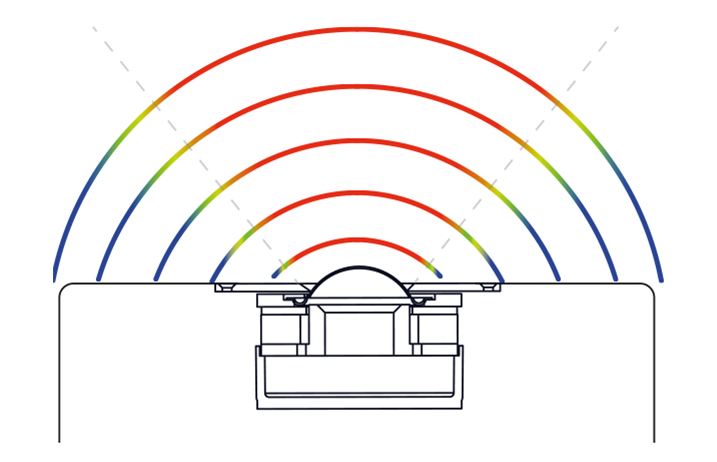

Waveguides - why do we use them?

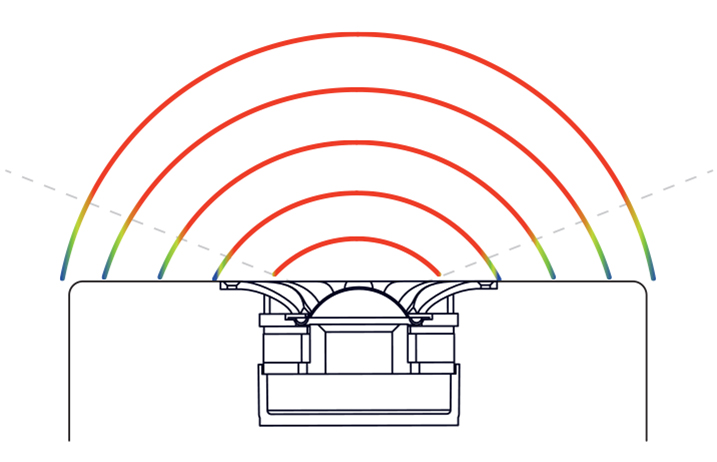

A waveguide is a structure that is placed around the front of a drive unit in order to shape , or guide the sound waves being produced by the drive unit diaphragm, ensuring that they leave the speaker in a uniform manner in all directions, giving a smoother, wider dispersion. A waveguide can also help to match the radiation impedance of a drive unit diaphragm to that of the air around it, allowing it to couple with the air more effectively and improving the efficiency of the driver. The result of this is a speaker with greater sensitivity and a more natural, effortless presentation of music that is consistent over a wide listening area.

PMC’s larger professional speakers are renowned for their mid-range dome drivers, which deliver critical detail and realism in the vocal and instrumental range. The three-way ci140 is the only model in the new ci series to feature a midrange driver, which was custom-made for this flagship. The all-new 50mm (2”) dome features n-compass™ technology — a new dispersion flange geometry for a flat-frequency response and phenomenal off-axis performance. This makes the driver ideal for horizontal or vertical placement, as in a cinema LCR system, providing an identical immersive audio experience from all listening positions. The wide audio picture created by the mid-range unit provides unrivalled vocal and instrumental clarity and realism, keeping the dialogue distinct from the score for the “real” movie experience.

Midrange dispersion patterns

Standard loudspeaker

PMC ci series with n-compass technology; extending the midrange dispersion for a consistent, immersive experience throughout the listening environment