The source of PMC’s legendary natural, realistic sound is the Advanced Transmission Line (ATL) bass-loading technology, professionally proven all around the world. Find out more below from the tech lab at PMC.

How does transmission line work?

A transmission line places the drive unit at the end of a long, highly damped tunnel which absorbs all the unwanted mid and high frequency energy that is radiated from the rear of the driver, but allows the lowest frequencies to exit the line in-phase with the frontal radiation from the drive unit, greatly enhancing its bass performance. The transmission line is effective over a wide bandwidth of around two octaves centred on the main resonant frequency of the line, and over this region it controls the motion of the drive unit, massively lowering distortion and raising the maximum possible output level. The resonant frequency of the transmission line is defined by the acoustic length of the line, and is the frequency at which one quarter of a wavelength is equal to the acoustic length of the transmission line.

Transmission line speaker design requires the balancing of many complex parameters and variables, from drive unit parameters, to line length, area, taper and profile, foam placement, thickness and specification etc. All of these parameters affect each other in complex ways, meaning that they must all be considered and optimised together in order to achieve an ideal result. The cost and difficulty involved in successfully achieving this is why PMC are one of so few companies to successfully develop transmission line speakers.

What makes ATL advanced?

Transmission line speakers are not a new concept, and have been around since the 1930s, although they were first popularised by Bailey in the 1960s. However, early transmission line speakers were prohibitively large and unwieldy, and suffered from a myriad of issues such as uncontrolled resonances, poor drive unit/transmission line coupling, unoptimized placement of drive unit/vents etc.

PMC has expended an enormous amount of time and money to research and develop the concepts behind transmission line speakers in order to bring out the full potential of these designs. Our first major development was in the specification of the absorbent foam we use to line our cabinets. This has given us exactly the right combination of mid and high frequency absorption, together with the control of low frequency resonances and the ability to alter the apparent acoustic length of the cabinet by effectively slowing the speed of sound as it passes through the foam. We have also developed the use of resonant absorbing chambers within the cabinet to allow us to further control specific unwanted resonant frequencies, reducing distortion and increasing the linearity of our speakers ...

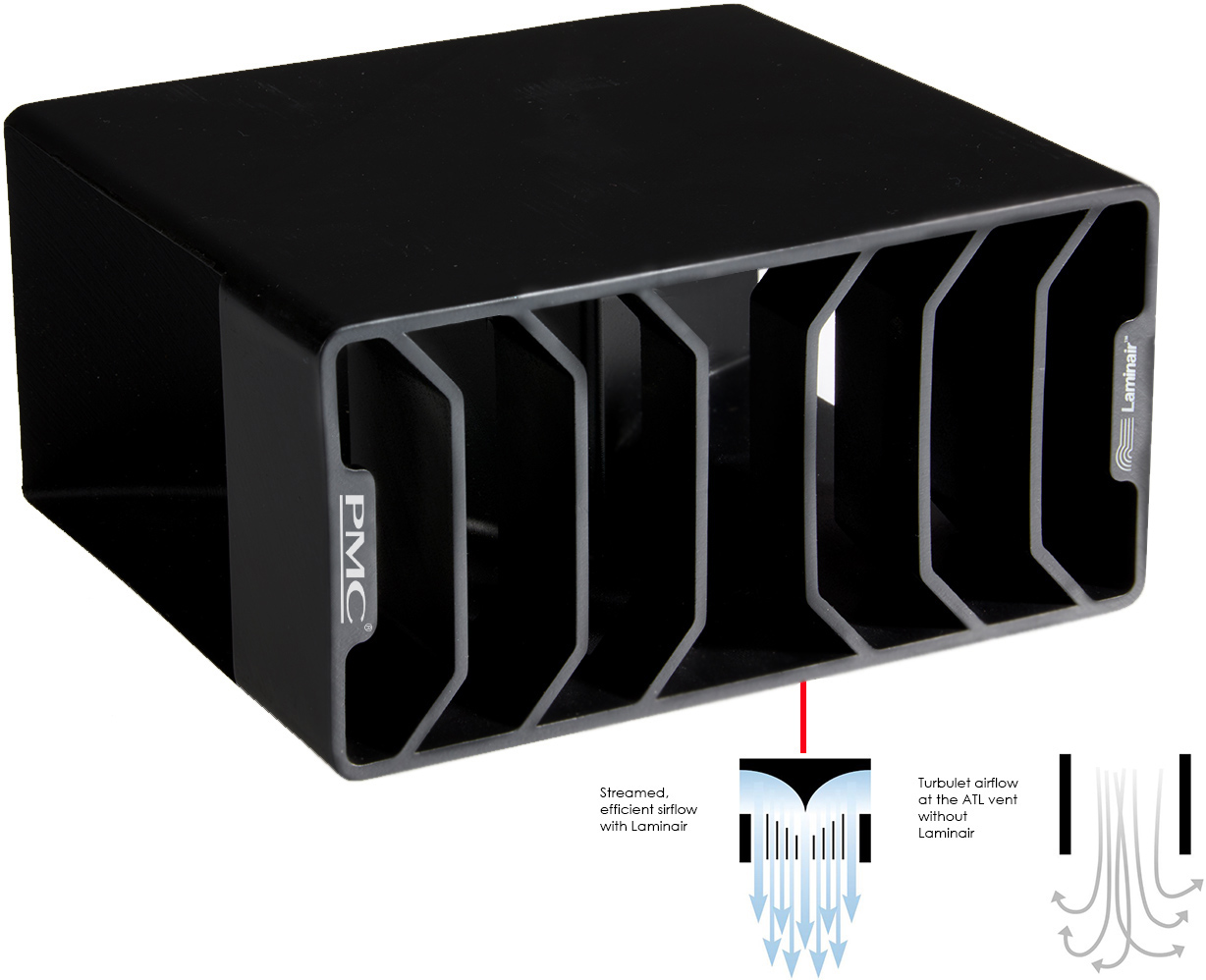

... More recently, we developed the laminair vent, which acts to smooth out the air flowing from the end of the transmission line by dividing it into multiple channels with a larger hydraulic diameter, resulting in massively reduced turbulence within the airflow. The result of this is that we can now play cleaner, louder bass with no unwanted ‘chuffing’ noise.

A significant amount of R&D effort is put into the drive unit design for each new speaker product/line. Because the parameters of the transmission line effect the behaviour of the drive unit and vice-versa, it is vital the cabinet and drive unit are developed in tandem in order to give the best possible performance from the final product. Transmission line cabinets also perform better with a very different set of drive unit parameters than would be common in most sealed and ported speaker designs. In order to achieve this, every single drive unit used in a PMC product is custom designed by PMC, with many being fully built in-house.

Deeper bass from a smaller cabinet

Across the frequencies where the transmission line is active, the air inside the line actually stiffens and couples to the back of the drive unit cone (this is how the cone motion is controlled by the transmission line). When this happens, the apparent moving mass of the cone is significantly increased, thereby lowering the effective resonant frequency of the drive unit. The effect of this is that the speaker can now produce significantly deeper bass, with greater headroom and less distortion than would be possible from that same drive unit in a sealed or ported cabinet.

Because the transmission line is so well damped with acoustic foam in order to absorb the unwanted mid and high frequencies radiated into the cabinet, the quality of the bass produced by a transmission line speaker is also incredibly accurate and well damped, with greatly improved time-domain characteristics than is seen in most simple ported speakers.

Same frequency response at all volume levels

Unlike the Helmholtz resonance that ported speakers use to increase their bass response, a transmission line does not change its efficiency with signal level. A ported speaker will lose bass output at low signal levels, as its port will not become efficient and active until a significant amount of energy is being input into the system. This is why many ported speakers wont ‘come alive’ until they are turned up fairly loud. Conversely, a transmission line speaker will retain its full, extended frequency response at all playback levels, meaning that it can be trusted to give completely accurate sound from intimate, low level monitoring sessions to full reference level playback.

Acoustically absorbent chambers

Whilst we make use of highly specified acoustic foams to absorb unwanted resonances and rear-radiation within our ATL speaker cabinets, sometimes we will find that there is a particular resonant frequency that would require an excessive amount of foam to completely damp, leading to an overly dry bass response from the loudspeaker. In these cases, we can make use of resonance absorbing chambers within the cabinet to target specific frequencies that we want to control. These chambers can be precisely tuned to specific frequencies, and can effectively remove these unwanted frequencies from the output of the ATL, leading to a completely clean, uncoloured sound from the loudspeaker.

Lower Distortion

The acoustic absorption within the transmission line means that no mid or high frequency energy is re-radiated through the cone from the cabinet. This and the fact that there is no excessive back pressure in the cabinet preventing the cone from moving freely at mid and high frequencies, means that transmission line speakers can give incredibly transparent and uncoloured midrange detail, and an effortless, unrestrained presentation to music.

Also, because the motion of the cone is controlled by the transmission line at the lowest frequencies, there is a significant reduction in driver excursion for a given level of bass output. This massively lowers distortion at low frequencies, as nonlinearities at high driver excursions are the most significant cause of low-frequency distortion.

Laminair - smoothing the air flow

PMC’s Laminair™ aerodynamic vent takes audio performance to the next level, by applying ATL aerodynamic principles from high-performance engineering used from F1 to Le Mans and creating an even smoother, laminar air flow at the exit from the transmission line.

ATL designs involve air moving at high speeds and under pressure.Reducing turbulence and drag at the ATL vent reduces resistance, increases efficiency, eliminates air noise and provides bass with supreme timing and the widest possible dynamic range.The combination of ATL and Laminair takes audio quality to unparalleled new heights:

- Faster, cleaner bass and higher definition sound throughout

- Turbulence is eliminated, increasing the efficiency of the ATL

- Removes air noise — only the music remains

- Higher maximum output and bass with supreme timing and dynamics

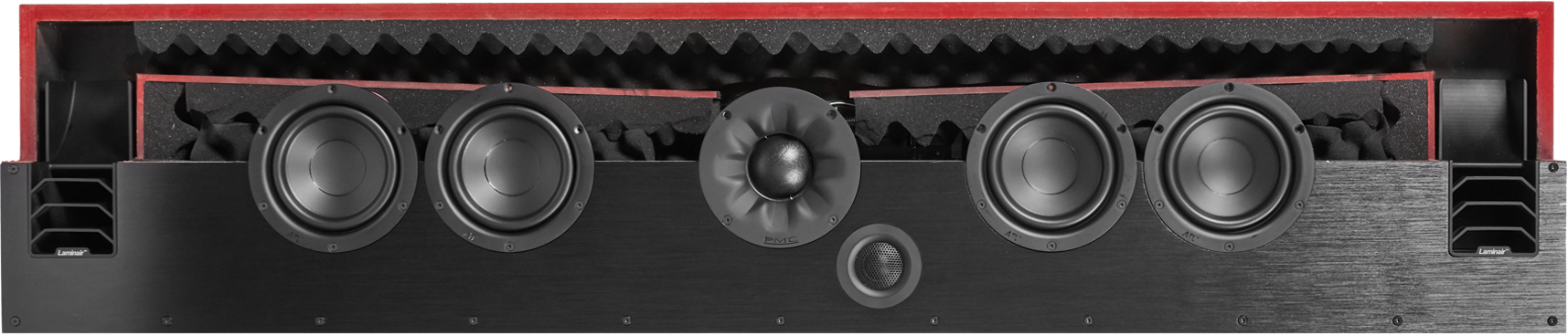

Advanced cabinet construction

Structural integrity and accuracy are the most crucial elements when making any loudspeaker enclosure, and with PMC’s holistic design approach every element has been considered to enhance performance. Forming both the cabinet and housing the sophisticated ATL™(Advanced Transmission Line) are precision machined panels of highly specified HDF material, some as much as 40mm thick. With the consumer veneered models, they are prepared both inside and out with veneer that guarantees their stability and long life.

The accuracy of the joints, together with modern bonding agents creates one homogeneous, flawless structure that acts as the ideal, inert platform for the drive units to deliver pure, uncoloured audio.